Home > News Announcement > Green Building Division > 5.88MW! Self-developed and self-constructed, self-generated and self-used project: Safety Tian's Mingguang base in Anhui rooftop distributed photovoltaic system is successfully connected to the grid.

5.88MW! Self-developed and self-constructed, self-generated and self-used project: Safety Tian's Mingguang base in Anhui rooftop distributed photovoltaic system is successfully connected to the grid.

On August 1st, the 5.88MW rooftop distributed photovoltaic power generation project at the Anhui Mingguang base, which was independently invested in and operated by SAFETY, passed the acceptance smoothly and successfully achieved full-capacity grid connection and power generation.

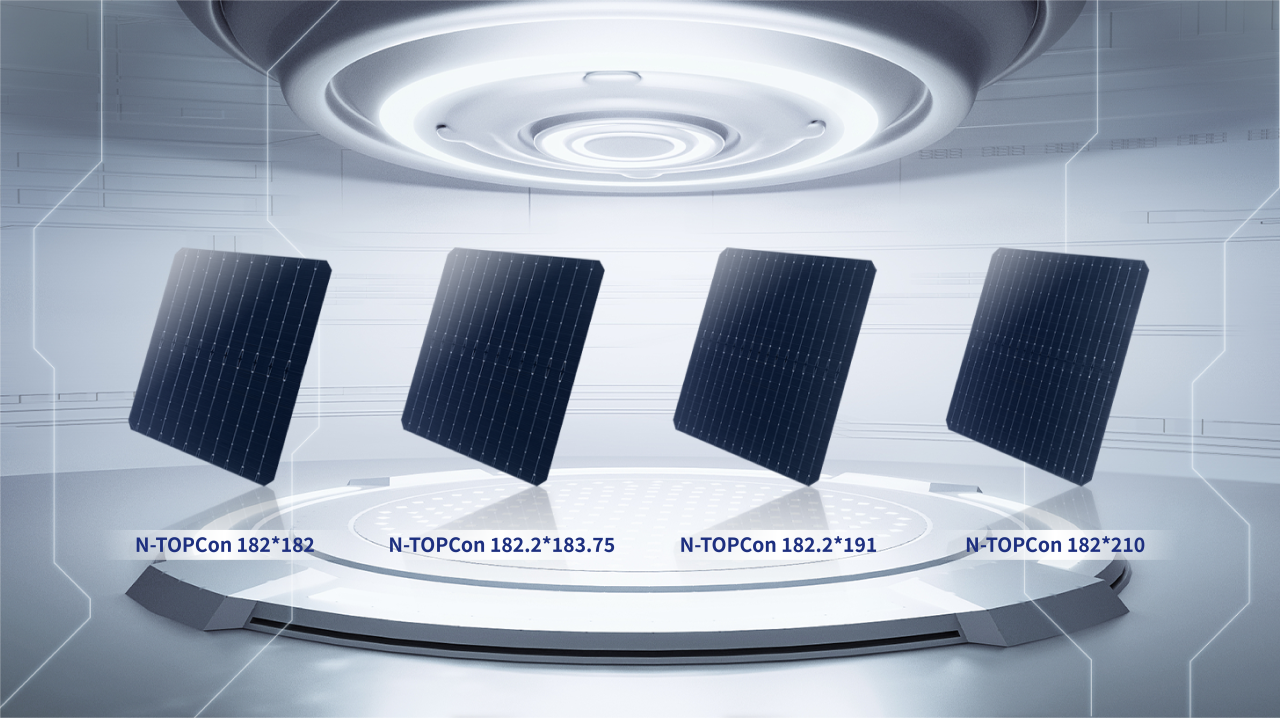

The project fully embodies the industrial synergy advantages of SAFETY, forming a joint force at every stage of the project. The Green Building Business Department of SAFETY is responsible for independent research and construction, providing EPC design and construction general contracting support; the Photovoltaic Business Department uses its own products, providing high-efficiency N-type TOPCon photovoltaic cell products. After being connected to the grid, it will adopt the "self-generation for self-use, surplus electricity to the grid" model. It is expected to achieve an annual power generation of over 6.23 million kWh, with a cumulative power generation of 155.75 million kWh over 25 years, which is equivalent to saving 2,048 tons of standard coal, reducing carbon dioxide emissions by 5,117 tons, and planting 280,000 trees, thus offering significant environmental benefits.

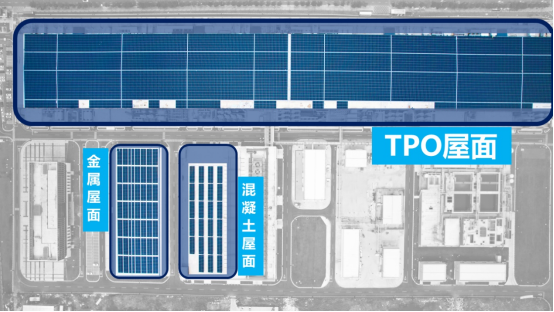

During the design phase, the Green Building Business Department of SAFETY closely followed the zero-carbon concept in various stages such as site survey, scheme design, and engineering management. Through design optimization of green building underlying logic, efficient use of clean energy and environmental protection materials, and effective supervision of energy consumption, the project achieved low carbon emissions throughout its lifecycle, building a green production system. During the construction phase, the project team managed the construction progress efficiently and treated the three different types of roofs in the project with different construction techniques. It took only three months to complete the entire process from design to grid connection.

1.TPO Roof: BIPV method is adopted to minimize the risk of roof leakage while maximizing the use efficiency of the roof and the installed capacity of photovoltaics.

2.Metal Roof: In conjunction with the original standing seam construction of the metal roof, metal clips are used for a simple and fast installation method without damaging the original metal roof panel

3.Concrete Roof: Concrete counterweights are used to obtain the best angle for the photovoltaic modules, improving the overall power generation of the photovoltaic power station

Quality Assurance - High-Efficiency N-type TOPCon Products